low temperature solvent extraction

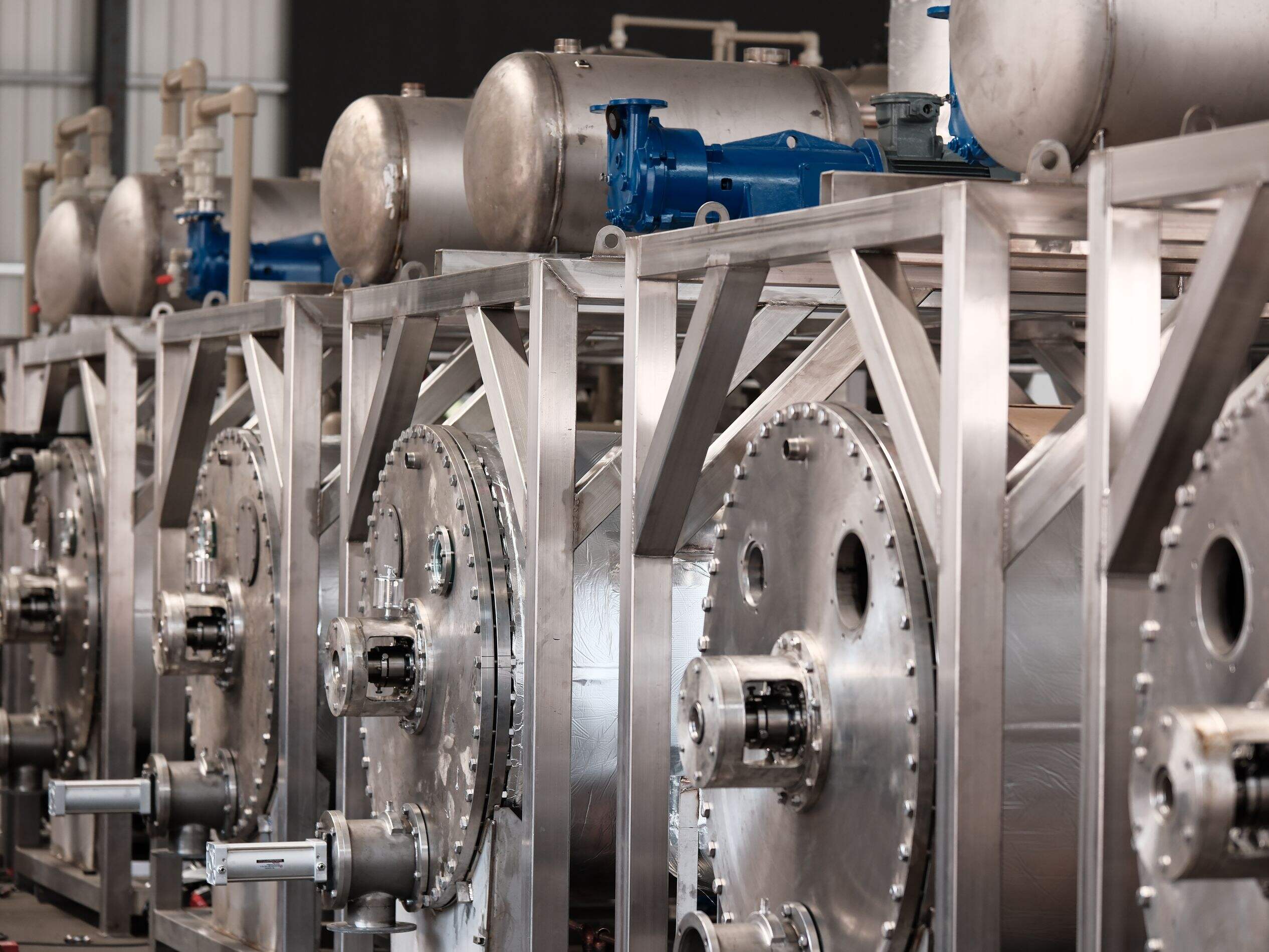

Low temperature solvent extraction is an advanced separation technique that operates at reduced temperatures to isolate desired compounds from various materials. This process involves using organic solvents to selectively extract target compounds while maintaining their integrity and quality. The technology employs sophisticated temperature control systems, typically operating between 30-50°C, which is significantly lower than conventional extraction methods. This gentle approach is particularly valuable for heat-sensitive compounds, such as natural oils, pharmaceuticals, and bioactive components. The process begins with the preparation of raw materials, followed by careful solvent selection based on the target compound's properties. The extraction occurs in specialized vessels equipped with precise temperature monitoring and control mechanisms. The low-temperature environment helps preserve the molecular structure of sensitive compounds, resulting in higher quality extracts. This method has gained significant traction in various industries, including pharmaceutical, nutraceutical, and food processing sectors. The technology also incorporates advanced filtration systems and solvent recovery units, making it both environmentally friendly and economically viable. Modern implementations often feature automated control systems that ensure consistent extraction conditions and reproducible results.