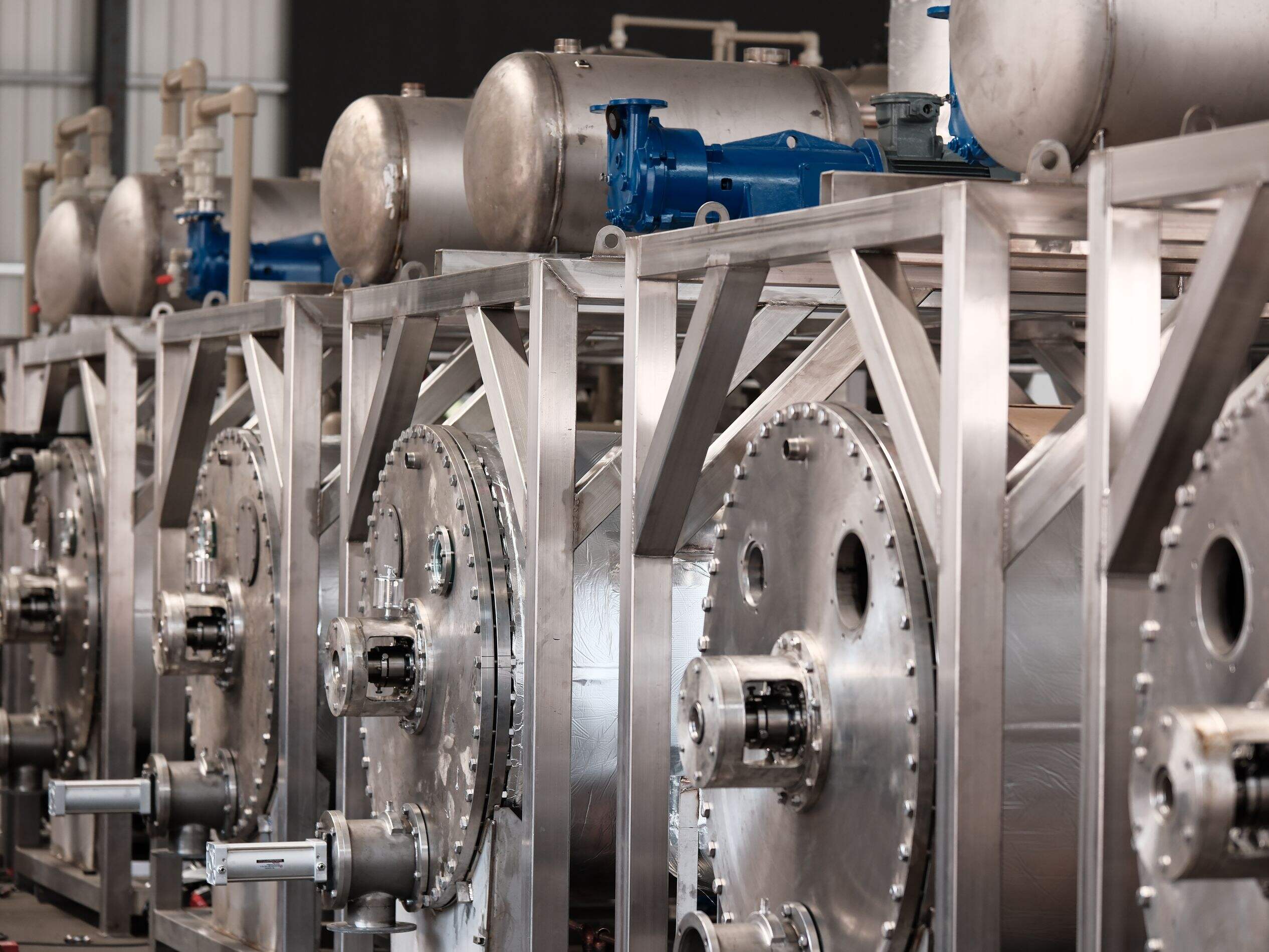

evaporator system for sale

The industrial evaporator system represents a cutting-edge solution for efficient liquid concentration and separation processes. This advanced system utilizes controlled heat and pressure manipulation to remove solvents, primarily water, from various solutions, resulting in concentrated end products. The system incorporates state-of-the-art heat exchangers, vacuum technology, and automated controls to ensure optimal performance across diverse applications. Designed with versatility in mind, it accommodates multiple industries including food and beverage processing, chemical manufacturing, and pharmaceutical production. The system features precision temperature control mechanisms, energy-efficient heat recovery systems, and sophisticated monitoring capabilities that maintain product quality throughout the evaporation process. Its modular design allows for easy scaling and customization based on specific production requirements, while the integrated cleaning system ensures minimal maintenance downtime. The evaporator system employs advanced materials resistant to corrosion and wear, extending operational lifespan and reducing maintenance costs. With capacities ranging from small-batch processing to continuous industrial-scale production, this system delivers consistent results while maintaining product integrity and meeting strict quality standards.