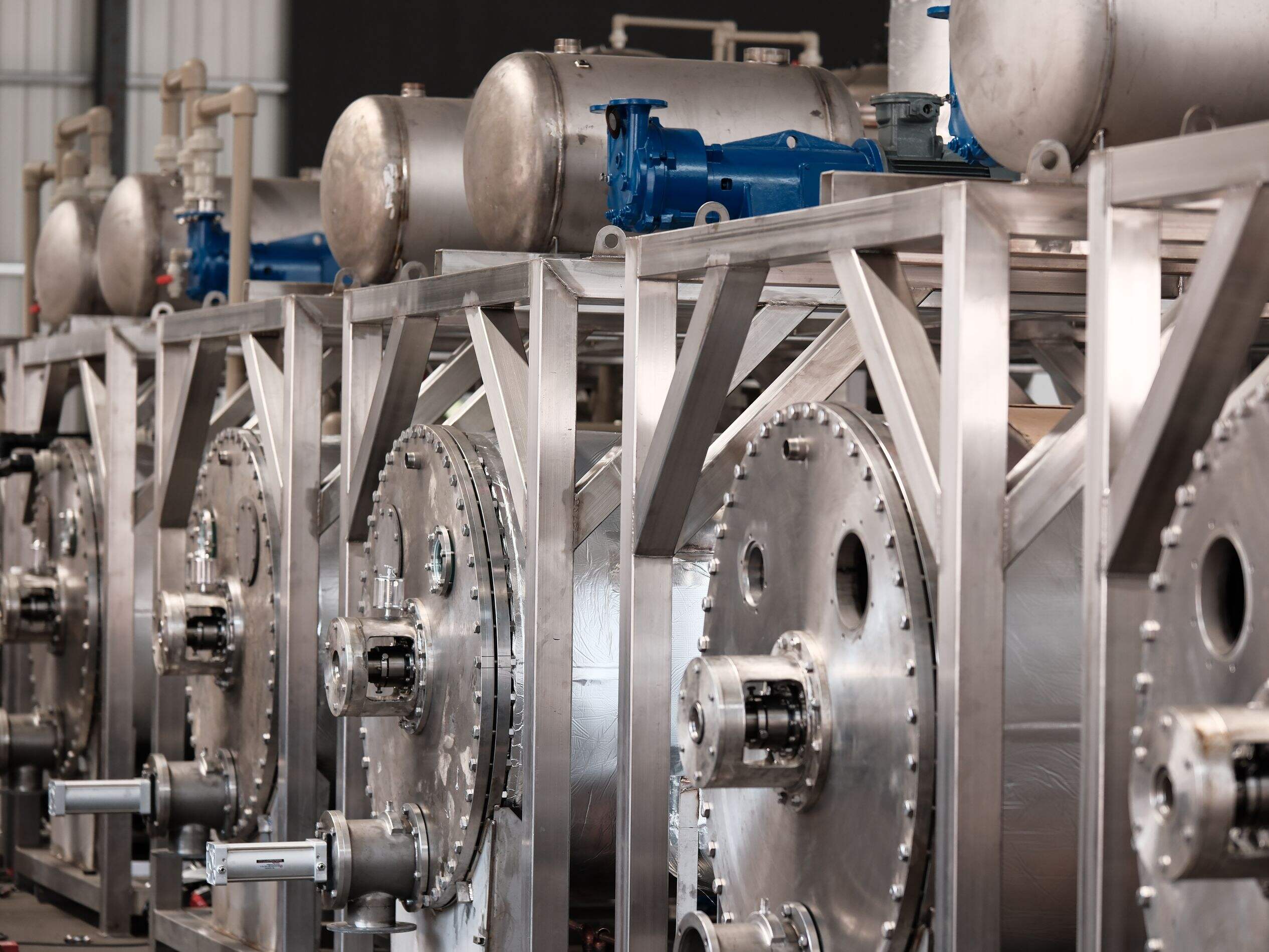

scraper crystallization process

Scraper crystallization is an advanced industrial process designed for efficient separation and purification of crystalline materials from solution or melt. This sophisticated technology employs mechanically operated scrapers that continuously remove crystal deposits from cooled heat transfer surfaces, ensuring optimal crystal formation and growth. The process begins when the solution or melt is introduced into a crystallizer vessel equipped with cooling surfaces. As the temperature drops, crystals form on these surfaces and are immediately scraped off by automated blades, preventing excessive buildup and maintaining consistent heat transfer efficiency. The scraped crystals then fall into the slurry, where they continue to grow under controlled conditions. This continuous operation enables precise control over crystal size distribution and purity levels. The technology finds extensive applications across various industries, including chemical processing, pharmaceutical manufacturing, and food production. Its ability to handle high-viscosity materials and produce uniform crystals makes it particularly valuable in specialized applications such as paraffin wax processing and specialty chemical production. The system's design incorporates features for temperature control, scraper speed adjustment, and product discharge management, allowing for optimization of the crystallization process based on specific product requirements and operational parameters.