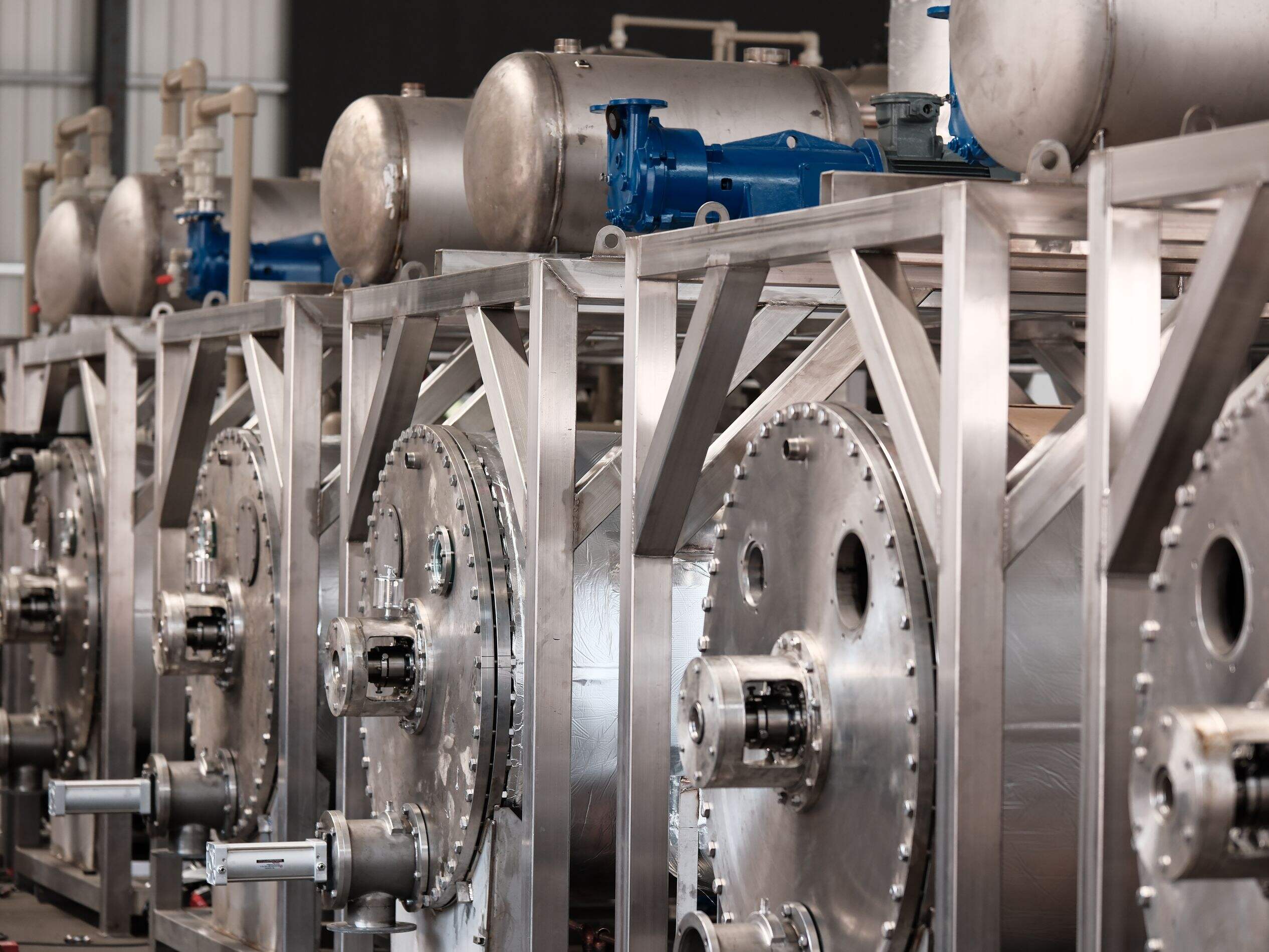

evaporator system factory

An evaporator system factory represents a state-of-the-art manufacturing facility dedicated to producing advanced evaporation solutions for various industrial applications. These facilities integrate cutting-edge technology with precision engineering to create systems that efficiently remove moisture from products through controlled evaporation processes. The factory encompasses multiple production lines equipped with automated assembly systems, quality control stations, and advanced testing facilities. Each production area is optimized for specific components, from heat exchangers to vacuum systems and control units. The facility maintains strict environmental controls and cleanliness standards to ensure product quality and consistency. Modern evaporator system factories utilize computer-aided design and manufacturing systems, allowing for customization of equipment to meet specific client requirements. The production process incorporates advanced welding techniques, precise machining operations, and rigorous quality assurance protocols. These facilities also typically include research and development departments focused on innovation and improving system efficiency. The factory's output serves diverse industries, including food and beverage processing, chemical manufacturing, pharmaceutical production, and wastewater treatment. With comprehensive testing facilities, each system undergoes thorough validation before shipment, ensuring optimal performance and reliability.